Some examples of use:

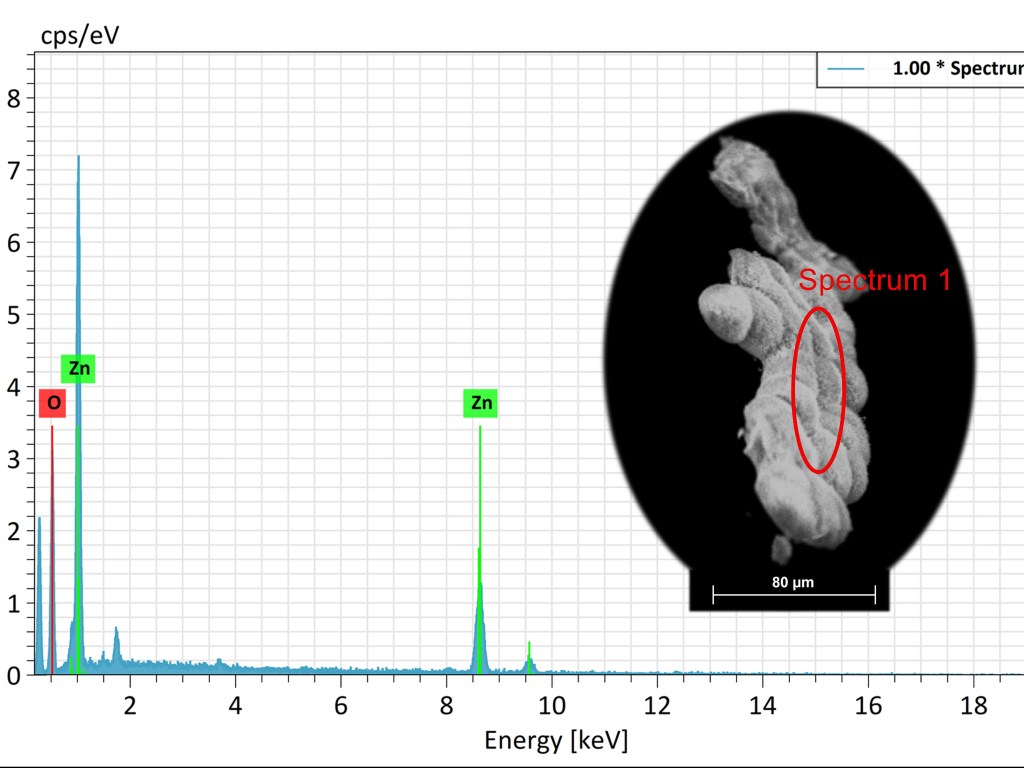

Determination of chemical composition by EDS (Energy Dispersive Spectroscopy) is an analytical technique used to identify and quantify the elements present in a sample. Coupled with a Scanning Electron Microscope (SEM), the EDS method detects the characteristic X-rays emitted by the atoms in the sample when they are bombarded by an electron beam. Each chemical element emits X-rays at specific energies, allowing for their identification and quantification in the analyzed material.

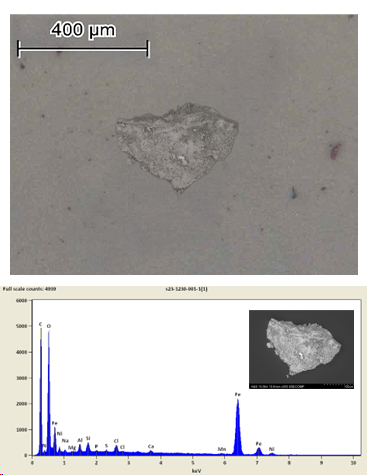

The identification of particles using a Scanning Electron Microscope (SEM) following a cleanliness test (ISO 16232) involves analyzing and characterizing contaminant particles collected from technical components. The ISO 16232 cleanliness test defines the methods for extracting, collecting, and analyzing particles. Using the SEM, the morphology and chemical composition of the particles are examined through Energy Dispersive Spectroscopy (EDS). This analysis determines the size, shape, and nature of the contaminants, helping to improve manufacturing processes and ensure component reliability.

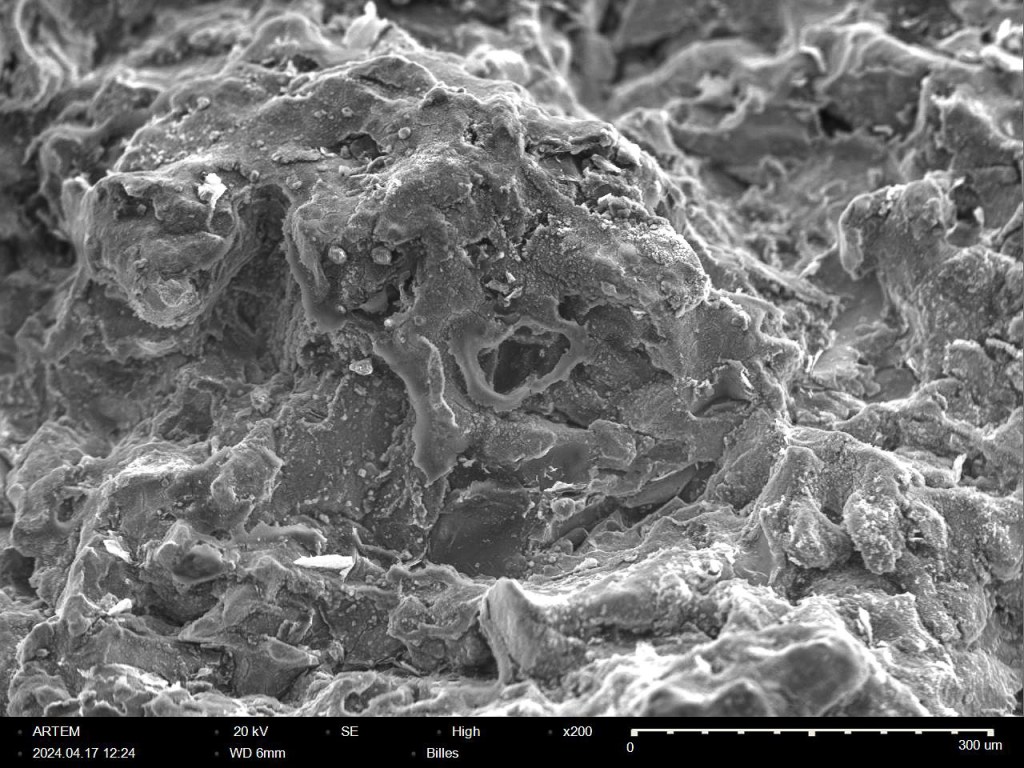

Fracture facies in Scanning Electron Microscopy (SEM) refer to the characteristics of the fracture surfaces observed on a broken material. Analyzing these facies allows for the identification of fracture mechanisms such as brittle, ductile, fatigue, or corrosion-induced fractures. The SEM provides high resolution and great depth of field, revealing microscopic details of the fracture surface morphology, such as fatigue striations, plastic deformation zones, or crystalline cleavages. This information is essential for understanding the causes of material failure.